Component Testing – Precision, Throughput, and Integration at Scale

Electrical testing solutions for electronic components, batteries, sensors and more

Built for the Realities of Modern Component Testing

Electronic components must meet increasingly demanding standards. Whether you’re testing resistors, capacitors, semiconductors, sensors, or microbatteries quality, consistency, and speed are everything.

Electrical component testing helps verify that each part performs as intended, identifying issues such as incorrect inductance, parasitic losses, or out-of-spec ESR before they affect downstream systems. It’s a critical part of both development and production.

At Sciospec, we support this process with highly flexible electrical testing solutions from benchtop LCR meters to fully integrated, high-throughput test stations.

Looking for a smarter way to test your components?

Who we are working with and for

Common Challenges in Component Testing

- Needing high measurement precision and repeatability

- Scaling test setups to high channel counts for throughput

- Integrating with automated systems and robotic handlers

- Handling conditioning + impedance testing in one flow

- Testing a broad range of components, from microbatteries to sensors

- Avoiding overpriced, overcomplicated lab equipment in production

You can’t compromise on test quality. But you also can’t slow down production. Or blow the budget. Or fight your equipment every time a new form factor is introduced.

That’s where Sciospec comes in.

Facing similar challenges in your test setup?

Read more about our solutions or contact us directly to discuss how we can support your workflow

The Sciospec Advantage Scalable without compromises

Other providers might offer a lab device. Maybe a few extra channels.

But when it comes to scaling up really scaling they hit the ceiling.

That’s where we’re just getting started.

Catalog Products That Already Go Further

- Precision, speed and flexibility out of the box

- Instruments like the LCR-3 and ISX series support not just 1 or 2 but up to hundreds of channels

- Real impedance spectroscopy, conditioning and advanced measurement modes

- Full software and hardware modularity

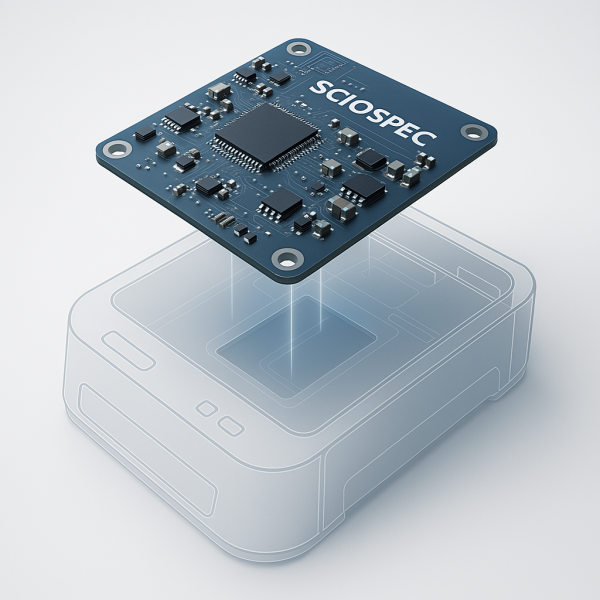

Modular Building Blocks for Real-World Scale

Our multiplexer systems and parallel architectures support:

- 32, 64, 128, up to 256 ports per instrument

- Seamless transition from lab to pilot to production

No one else offers this range as a standard offering

And Then the Magic Starts

When other suppliers run out of options and when conventional engineering firms lack the specialized know-how we’re just getting warmed up.

- We build fully customized massive multichannel systems

- With exact tray layouts robotic integration,test sequencing and conditioning logic

- All powered by the same proven measurement platform trusted by researchers, developers, and manufacturers worldwide

From 1 to 4096+ channels ! Sciospec is the only partner who grows with you !

References & satisfied customers

Reference Case: TDK/Epcos CeraCharge Production Testing

When TDK/Epcos prepared to scale their CeraCharge microbattery production they needed a solution that delivered:

- Lab-grade impedance spectroscopy

- Complex conditioning cycles

- 512 channels all running in full parallel

- Seamless integration into existing robotic and automation systems

Sciospec delivered with performance, cost-efficiency and integration no other platform could match.

Curious how we handle high-channel, high-performance setups like this?

Explore our FAQ section to learn more or contact us to discuss your specific requirements.

Lab-grade impedance testing at full parallel throughput no other platform could have delivered that

Project Lead in charge of transitioning CeraCharge testing from R&D to production, TDK/Epcos

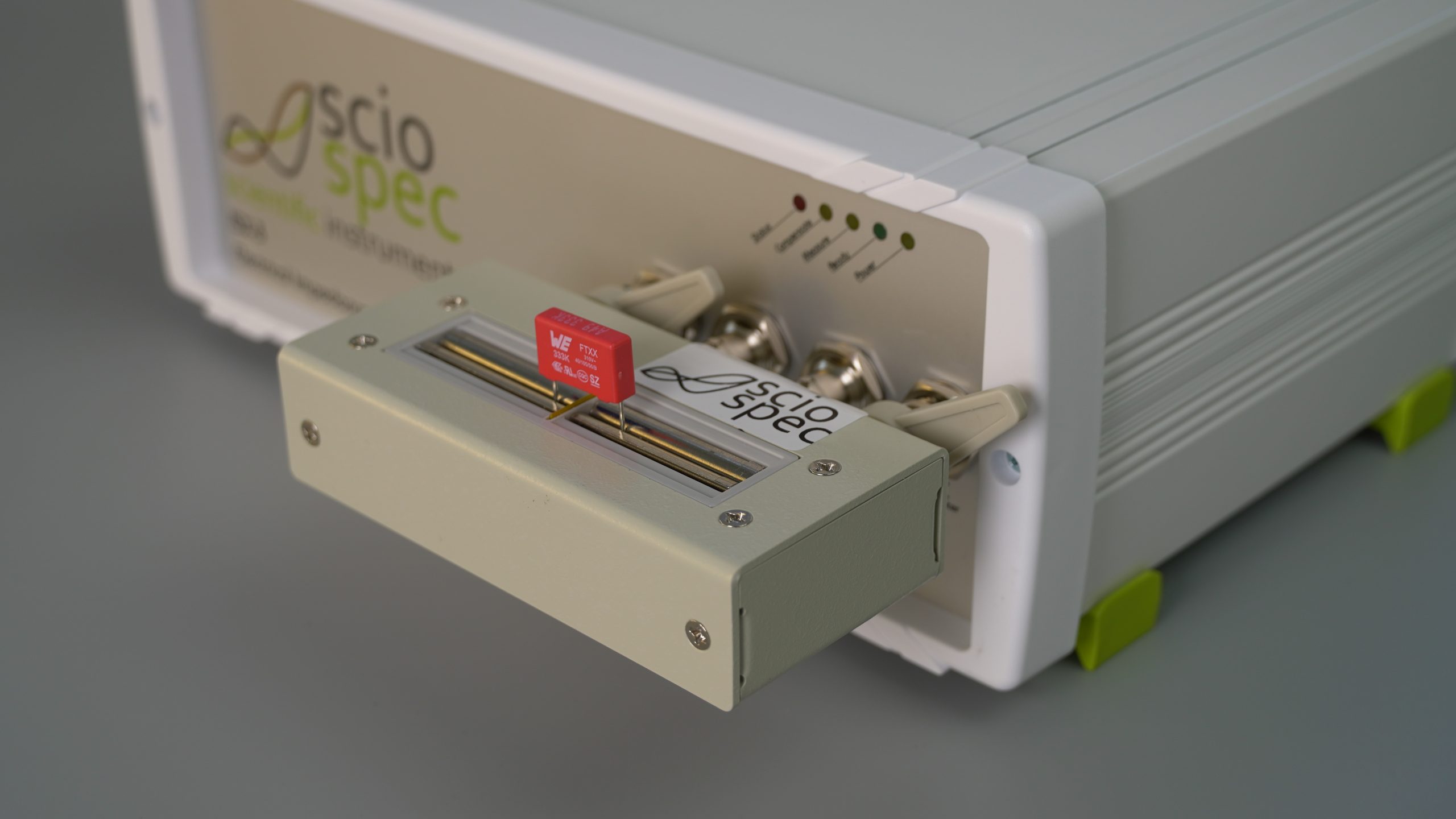

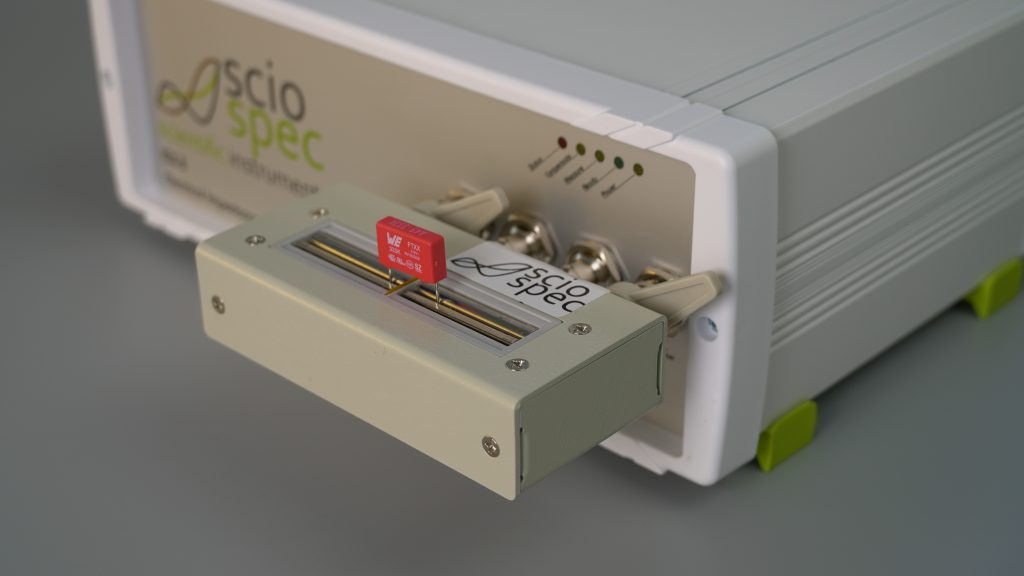

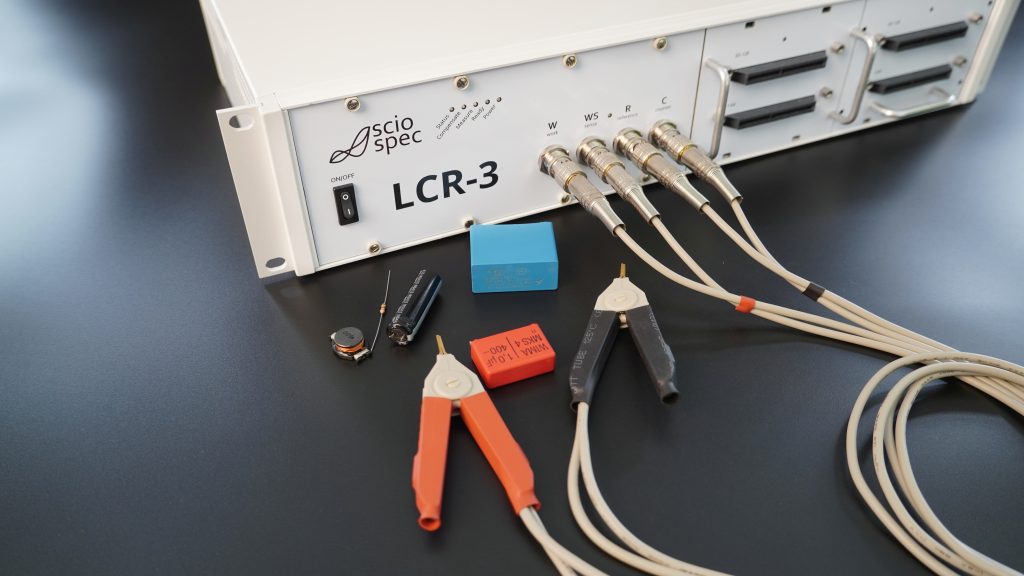

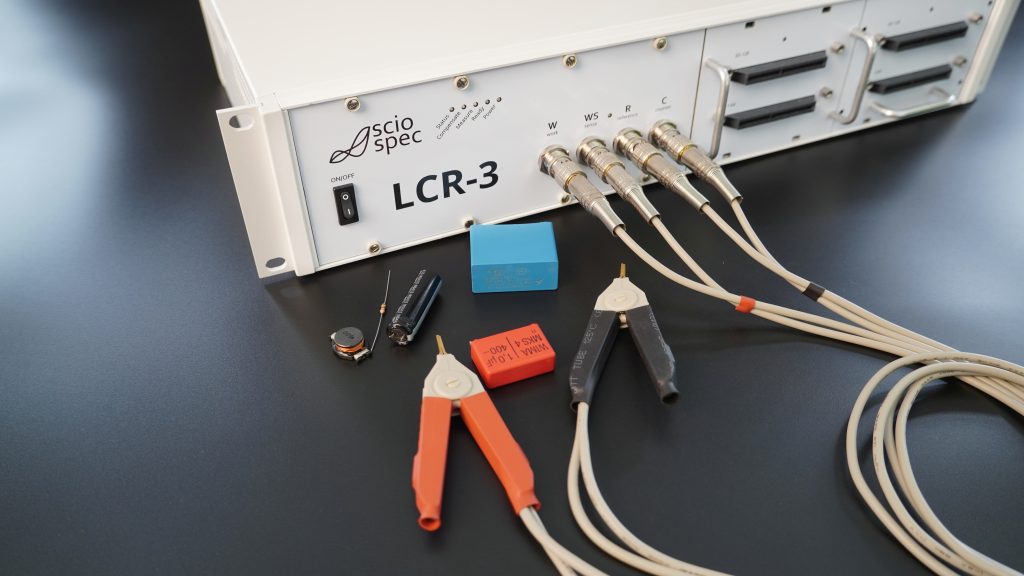

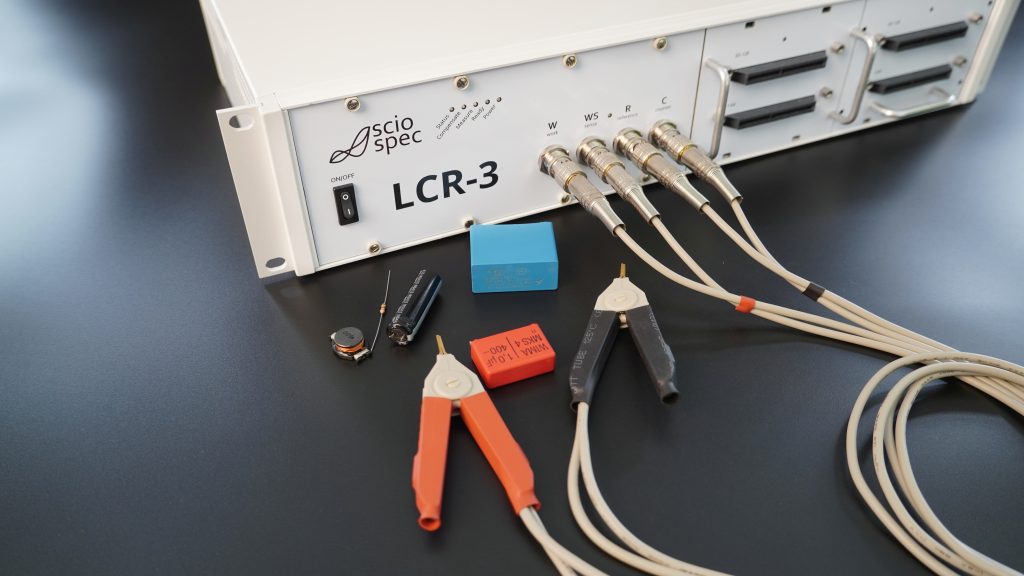

Not Ready for Full Scale Yet? Start with the LCR-3

Many of our partners begin with our modular benchtop instruments before scaling up.

The LCR-3 is perfect for component characterization, pre-production screening, or custom test rig development and it’s built on the same core platform as our OEM solutions.

Why Sciospec for Component Testing ?

- We cover the full spectrum from R&D to production from single-channel to 4096+ channels

- Our standard instruments already outperform most custom setups

- We’re the only partner combining deep impedance expertise with scalable OEM integration

- Our systems are built to match your components, processes, and automation environment not the other way around

Whether you’re launching a prototype or optimizing a global production line Sciospec builds test systems that grow with you.

Let’s Build Your Ideal Test System

We support you at every step:

- Modular instruments that grow with your needs

- Custom integrations that fit your production setup

- Engineering collaboration that respects your timelines and constraints

Frequently Asked Questions – Component Testing Solutions

Electrical component testing ensures that resistors, capacitors, sensors, microbatteries and other devices meet their specifications before use in assemblies or final products. It helps manufacturers identify faulty or substandard parts early, improving yield and reducing warranty risk. Sciospec provides high-precision electrical test systems for both R&D and production environments.

Key techniques include impedance spectroscopy, LCR (inductance, capacitance, resistance) measurements, and electrochemical analysis. Sciospec specializes in electrical impedance spectroscopy and LCR testing, offering unmatched measurement range, flexibility, and speed.

For production or inline testing, systems must be fast, scalable, and automation-ready. Sciospec’s modular architecture allows full-parallel or multiplexed systems with hundreds or even thousands of channels as demonstrated in our TDK/Epcos reference project.

Yes. Impedance spectroscopy can provide deeper insights into material properties and functional behavior, especially for advanced components like microbatteries, sensors or multilayer capacitors. Sciospec’s platform enables high-speed, high-resolution impedance testing at scale.

We offer solutions from single-channel benchtop instruments (like the LCR-3) to fully customized OEM systems with 4096+ channels. Our scalability is unmatched enabling you to grow from prototype to production without switching platforms.

Absolutely. Sciospec systems are designed with automation in mind: digital I/O, Ethernet, open APIs, and form-factor customization ensure seamless integration into robotic handlers, tray changers, or conveyor-based QA systems.

Yes. Whether you need a specific connector, tray layout, test sequence, or conditioning routine our modular and OEM solutions are tailored to your application. That’s where Sciospec goes far beyond standard instruments.

Definitely. Our LCR-3 and ISX-3/5 impedance analyzers offer a simple way to begin testing, with the same high-performance core technology that powers our OEM systems.

No one else offers both powerful catalog instruments and massive, fully customized multichannel solutions. With Sciospec, you’re not limited by standard boxes you gain a partner who can build what your process truly needs.

Still have questions? Contact us