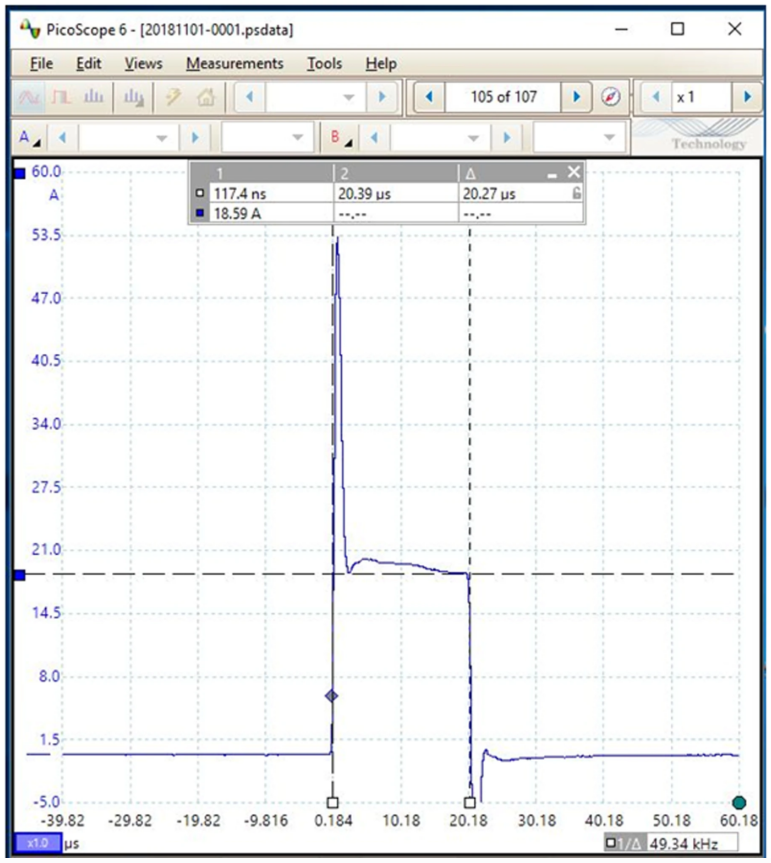

Enhancing water diffusivity shortens meat processing time and saves energy and costs. One of the processes that can enhance water diffusivity in tissues is high-voltage, short-pulsed electric fields (PEF). However, for industrial PEF process development, there is a need in adaptable laboratory instruments. Here we report on a laboratory PEF generator, based on insulated-gate monopolar transistor switching, coupled with sliding positive electrode for the enhancement of water diffusivity in chicken breast muscle. The system generates rectangular monopolar pulses with a voltage amplitude up to 1000 V, current up to 160 A, pulse duration of 5 to 100 μs, and a frequency of pulse repetition of 1–16 Hz. The energy conversion efficiency of the developed PEF generator is 88%. We found that applying 120 pulses at 1000 V (~ 500 V mm−1), and a pulse duration of 50 μs at 1 Hz, on the chicken breast muscle, increased the effective diffusivity of water by 13–24% and reduced convective air drying time by 6.4–15.3%. These results provide new information on the design of laboratory equipment to improve and optimize meat pre-processing on a small scale. Flexible, small-scale PEF equipment is a necessary step for the industrial development of new processes which could reduce equipment size and process energy consumption in the meat industry.

A Laboratory IGBT-Based High-voltage Pulsed Electric Field Generator for Effective Water Diffusivity Enhancement in Chicken Meat