LCR Meters for Precision Component Testing and Automated Integration

LCR Meters

Sciospec’s LCR meters deliver high-performance measurement solutions tailored to both research and industrial applications. Built on our proven impedance measurement technology, the LCR-1 and LCR-3 combine accuracy, speed, and flexibility. Whether you need a compact benchtop device or a scalable system for automated testing, our LCR meter solutions are engineered to meet the demands of modern component analysis.

🔎 Looking for a precision in a compact form Discover the LCR-1

⚙️ Need a solution for component testing? Explore the LCR-3

What Is an LCR Meter and How Does It Work?

The LCR meter is a specialized electronic test instrument used to measure electrical properties, specifically the inductance (L), capacitance (C), and resistance (R) of electronic components or other objects. The name “LCR” reflects the three basic types of passive electronic components that the meter is designed to analyze. Typical measurements determine not only a single L, C or R component, but combinations thereof, for example simple series or parallel circuits of RC or LC combinations.

The LCR meter applies an AC voltage or current signal to the component under test and then measures the voltage across the component. By analyzing the phase shift and amplitude of the voltage and current waveforms, the LCR meter can determine the values of inductance, capacitance, and resistance or combinations thereof. The results are evaluated in terms of equivalent circuit models.

🔍Need help choosing the right LCR meter? Contact our team for expert advice.

Our LCR Meters

High‑Precision LCR Meter Uses in Quality Control, Component Testing & Research

More advanced instruments are also capable of doing measurements on more complex component configurations. They therefore employ measurement modes using multiple frequencies, very similar to the operating principle of an impedance analyzer.

LCR meters are widely used in electronics manufacturing, research and development, quality control, and troubleshooting. They are essential tools for characterizing and testing various electronic components, such as capacitors, inductors, and resistors, to ensure they meet specified electrical parameters.

⚙️ Compare your options: Learn more about the LCR-1 and LCR-3

LCR Meters vs Impedance Analyzers: Key Differences

Most commercially available LCR meters are rather straight forward instruments intended for testing electrical components for their specifications, e.g. equivalent series resistance (ESR) and equivalent series inductance (ESL) measurements on capacitors. For this purpose, no spectral resolution is required and thus LCR meters usually only have a few selectable test frequencies. More advanced instruments also offer sweep functions and can be used for multifrequency measurements as seen in impedance spectroscopy. The disadvantages over the instrument class of impedance analyzers are subtle, but noticeable: typical measurement speeds of LCR meters will be lower and sweep point counts limited compared to impedance analyzers.

LCR meters are best put to use for testing electrical components. Advanced LCR meters also offer additional modes like frequency sweeps, time lapse measurements or pass/fail testing and typically perform best in manufacturing level component testing applications. In these, they are argueably the most suitable instrument class. For more advanced capabilities and measurement settings the instrument class of impedance analyzers typically presents a better fit.

Who we are working with and for

Application scenarios for LCR meters

An LCR meter is a specifically designed for measuring the electrical properties of passive electronic components most commonly inductors, capacitors, and resistors. Common application scenarios for LCR meters and reasons why you might use them inclu

🔍 Component Characterization

LCR meters are used to measure the inductance of coils and windings. This is essential in designing and testing electronic circuits, especially in applications like power supplies and transformers. LCR meters can measure the capacitance and equivalent series resistance (ESR) of capacitors, which is crucial for selecting the right components in circuits involving timing, filtering, and energy storage. While dedicated resistance meters and top of the line multimeters will typically be the best choice for measuring plain resistance at maximum accuracy, an LCR meter will give far more detailed insights. Real life resistors also include parasitic components (both capacitance and inductance). Selecting the right resistor for a given application is essential in more demanding electronic designs especially when working at higher frequencies or especially low or high resistance values. The LCR meter allows determining all these component characteristics and thus plays a big role in selecting capacitors, inductors as well as resistors for a given design

🏭 Quality Control in Manufacturing

LCR meters are employed in quality control and manufacturing processes to ensure that components meet specified tolerances. This is crucial for maintaining the quality and performance of electronic devices. LCR meters can be integrated into automated testing systems, allowing for efficient and high-throughput testing in production environments.

Application scenarios for LCR meters

🧰 Circuit Design and Troubleshooting

When diagnosing issues in electronic circuits, an LCR meter can help identify faulty or out-of-spec components. It allows engineers to pinpoint the exact nature of problems related to inductance, capacitance, or resistance. In the design of passive networks and filters (e.g., low-pass, high-pass, band-pass), LCR meters are used to measure and verify the values of inductors and capacitors, ensuring the filter meets the required specifications.

🧪 Material Testing

LCR meters can be used for material testing, especially in industries where materials with specific electrical properties are required. For example, in the automotive industry for testing materials used in sensors and actuators.

🎓 Education and Research

In educational settings and research laboratories, LCR meters are essential tools for teaching and conducting experiments related to electrical circuits and components.

In summary, LCR meters are versatile tools that play a crucial role in ensuring the proper functioning and quality of electronic components and circuits. They are widely used in various industries, from electronics manufacturing to research and development.

📩 Contact our team for tailored recommendations or integration su

Looking to Embed LCR Measurement into Your Product?

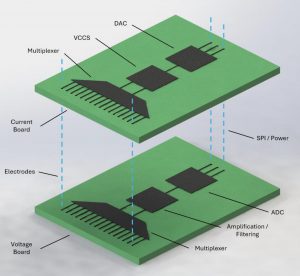

Integrating LCR measurement capabilities into complex setups and products takes time and ressources. Don’t let this slow your innovation or inflate your R&D budget. Sciospec`s proven measurement technology allows your team to seamlessly embed ready to go solutions directly into your system. We handle the measurement complexity so you can focus on your unique value proposition.

Tailored to Your Needs: Whether you require higher channel counts, specialized connectivity, custom form factors, or seamless integration into automated test setups – we provide the adaptability to make it work for you.

Leverage our validated LCR technology to significantly shorten your design cycle and get your product to market faster, instead of developing sensitive analog hardware from the ground up.

Ready to streamline your product development? Contact us today to discuss your specific OEM requirements, or visit our OEM solutions page for more information on integrating Sciospec LCR technology.

The right LCR meter for every need – Sciospec´s product range

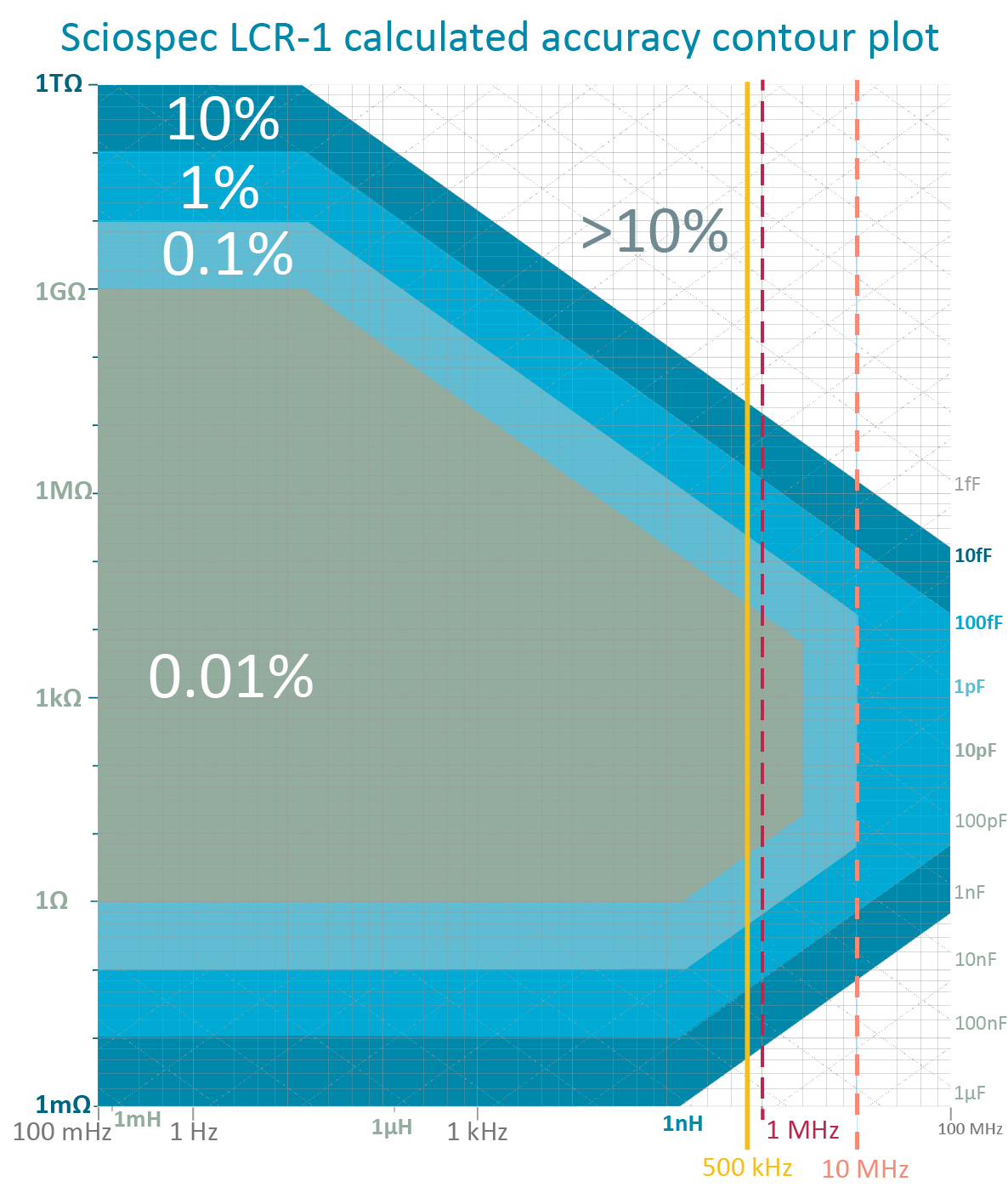

For all component testing scenarios, the Sciospec LCR-1 packs just the right features. Based on the same technology as our industry leading impedance analyzers the LCR-1 combines next-level performance with the simplicity of an LCR meter. In terms of range, accuracy and speed the LCR-1 sees eye to eye with competing high-end devices while maintaining a compact formfactor, simple setup and ease of use previously unseen in this class. Ranging from 1 mΩ … 1 TΩ, 10 fF … 1 kF, 1 nH … 1 TH the LCR-1 is specified for 0.01% base accuracy and an impedance range only challenged by top of the line impedance analyzers. The large selection of compatible test adapters enables all commonly seen component and material test scenarios and the modern, easy to use software user interface makes testing a breeze.

For more advanced capabilities and even more options you can also consider our impedance analyzer product range.

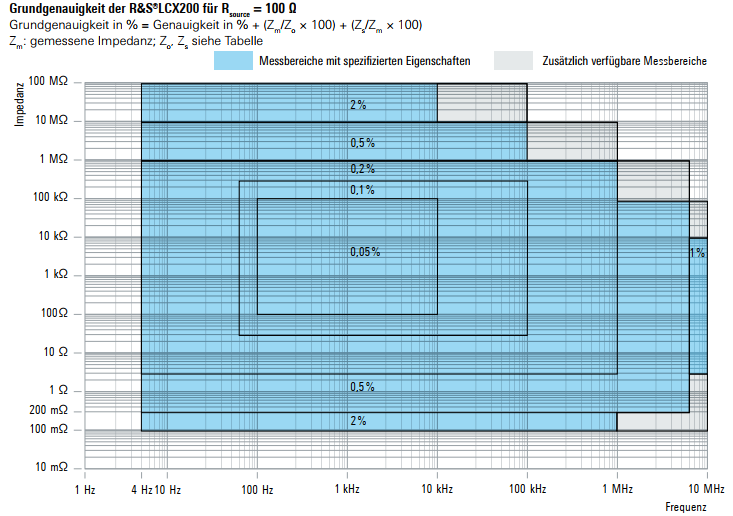

LCR meter specifications – what to watch out for

In general, LCR meters work on similar principals as impedance analyzers and the same parameters are to be considered. When measuring electrical impedance, main specifications are frequency and impedance measurement ranges, accuracy, speed and points per sweep. Just as important are requirements of the test setup like 2, 3 or 4 electrode configuration, bias control and scalability – when it comes to multichannel or high throughput problems. Since most applications require special care contacting a “device under test” the interface and extension possibilities of the instruments are also to be considered. Looking at instruments for impedance spectroscopy it is essential to look deeper than just the plain key specification from a product summary. Accuracy and speed both are at least dependent on frequency and absolute value of the measured impedance. Most manufacturers will specify across a very large range of impedances and frequencies, but a closer look into the datasheet will reveal that only certain range are covered in full accuracy. The distribution of them strongly varies across instruments. Thus, it is important to look at the accuracy-contour plots (see example below) showing which accuracy can be obtained at what absolute value and frequency. For a detailed comparison of specifications for the most widely used impedance analyzers on the market, check out this article. In simplified terms, LCR meters oftentimes are characterized not in terms of impedance ranges, but in terms of L, C and R ranges. For example, the Sciospec LCR-1 works for R = 1 mΩ … 1 TΩ, C = 10 fF … 1 kF, and L = 1 nH … 1 TH. However, in most cases it is important to measure at a specific test frequency and for that purpose the accuracy contour plots are the best option to understand an instrument´s capabilities. Notice how some of these include scales for inductance and capacitance values for easier readability.

Relevant publications