Setup

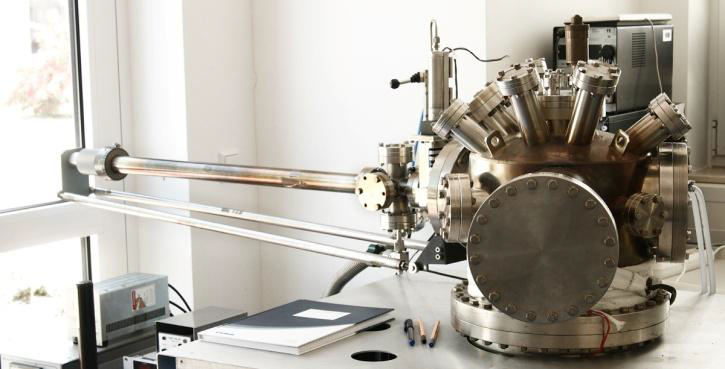

A high vacuum chamber, with a base pressure of 10^(-7) mbar, was employed to deposited Poly(Bisphenol-A-carbonate) via thermal evaporation.

Measured Data

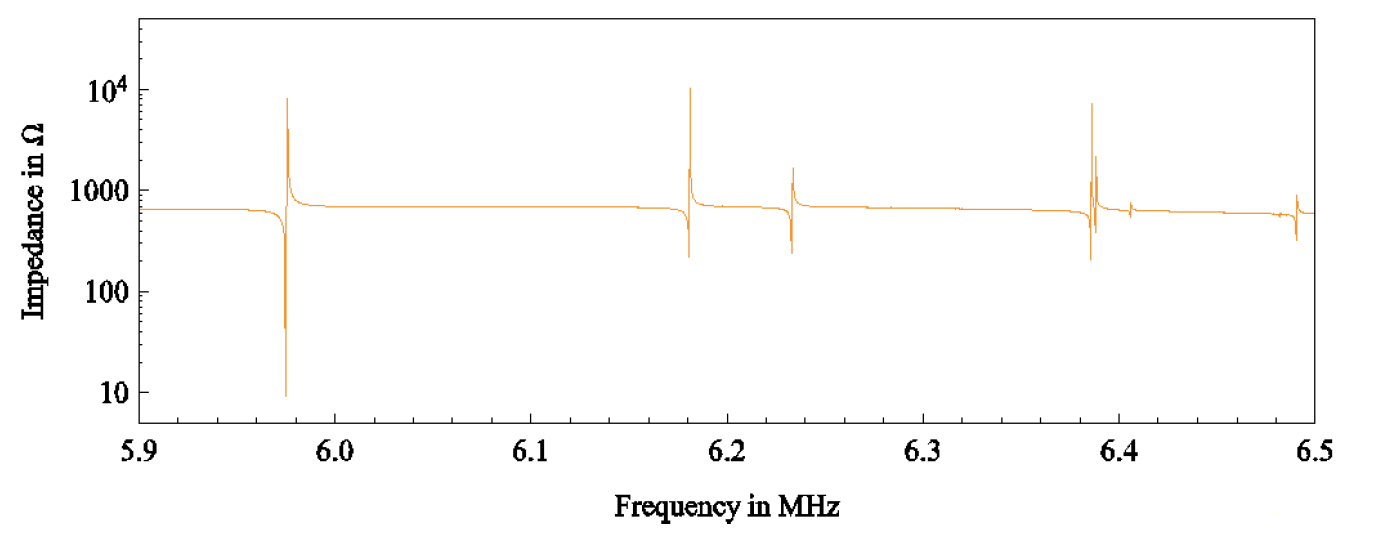

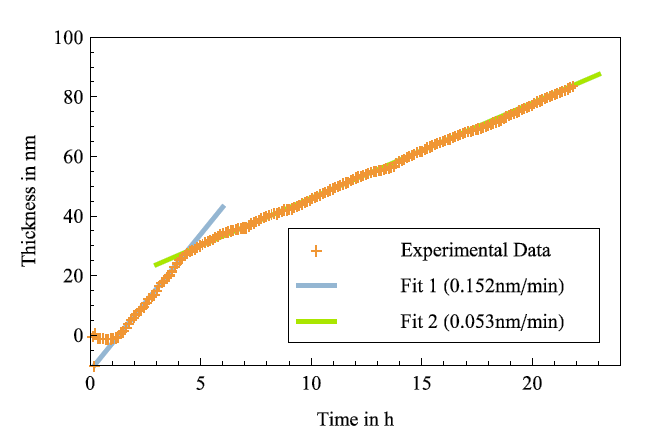

All the data has been displayed and stored with the Sciospec Impedance Analyzer Suite. The resonance frequency was tracked by peak fitting for each spectrum (Fig 2). The resulting frequency change was translated into the thickness (given in nanometers [nm]) of the deposited PBA (Fig 3) by the well known “Sauerbrey”- equation. This allows for a very sensitive in situ monitoring of the deposition process, which has been proven to be a useful approach in this kind of setting.

Evaluation

The data divides into three intervals. The first corresponds to the heating of the PBA. The evaporation temperature of about 230°C is reached after approximately one hour. This interval shows no relevant change in the spectra since no material is deposited. The temperature is still rising to 300°C at one and a half hour and then held constant over the complete process. After about one hour the temperature is therefore high enough so the deposition started at a rate of about 0.152 nm per minute. This seems to correspond to the formation of unconnected isles of PBA on the gold surface of the quartz crystal. The third interval starting at about four and a half hours after the beginning is not yet fully understood. The deposition rate abruptly changes to about one third (0.053 nm per minute) of the initial rate. This coincides with the formation of one single layer of the deposited material. Therefore a connection of the islands of the material seems to be a good possibility. Closer studies in combination with atomic force microscopy (AFM), best in situ, will be needed for a better understanding of this formation process. The final thickness of 84 nm has also been rechecked by X-ray reflectivity measurement to be correct in the range of one nm.

Outlook

Closer analysis of the secondary modes of the impedance spectrum have revealed clues to the nanostructrural formation within the coating process. Further investigation will lead to a closer understanding of the adhesion of the PBA molecules to the gold surface. As mentioned above, a study including AFM measurements in combination with even higher resolution impedance spectroscopy on resonant high-Q systems will to be the next step. Sciospec in cooperation with the AG Mayr1 is developing a fully integrated quartz crystal microbalance sensor with automatic temperature control for the use in ultra-high vacuum applications. The sensor will attach seamlessly to the existing Sciospec products and will be integrated in the Sciospec control software for easy to use setup. In this experiment the Sciospec ISX-3 system proofed to be an effective measurement tool for online inprocess monitoring in coating applications.