- automating sequential multi-sensor probing over

- the need of scaling up experiments to more throughput via parallel experiments

- complex multi-electrode arrangements with need for specific synchronized control

- simultaneous comparison of a single or a set of test targets/sensors to a single or a group of reference sensors

As diverse as the reasons for using multichannel arrangements are the choices for solutions. In general, there are four basic approaches:

- multiple single-channel potentiostat / galvanostat

- multiplexing

- multi-potentio-/galvanostat

- poly-potentiostat

Download our Multichannel Potentiostat Topologies

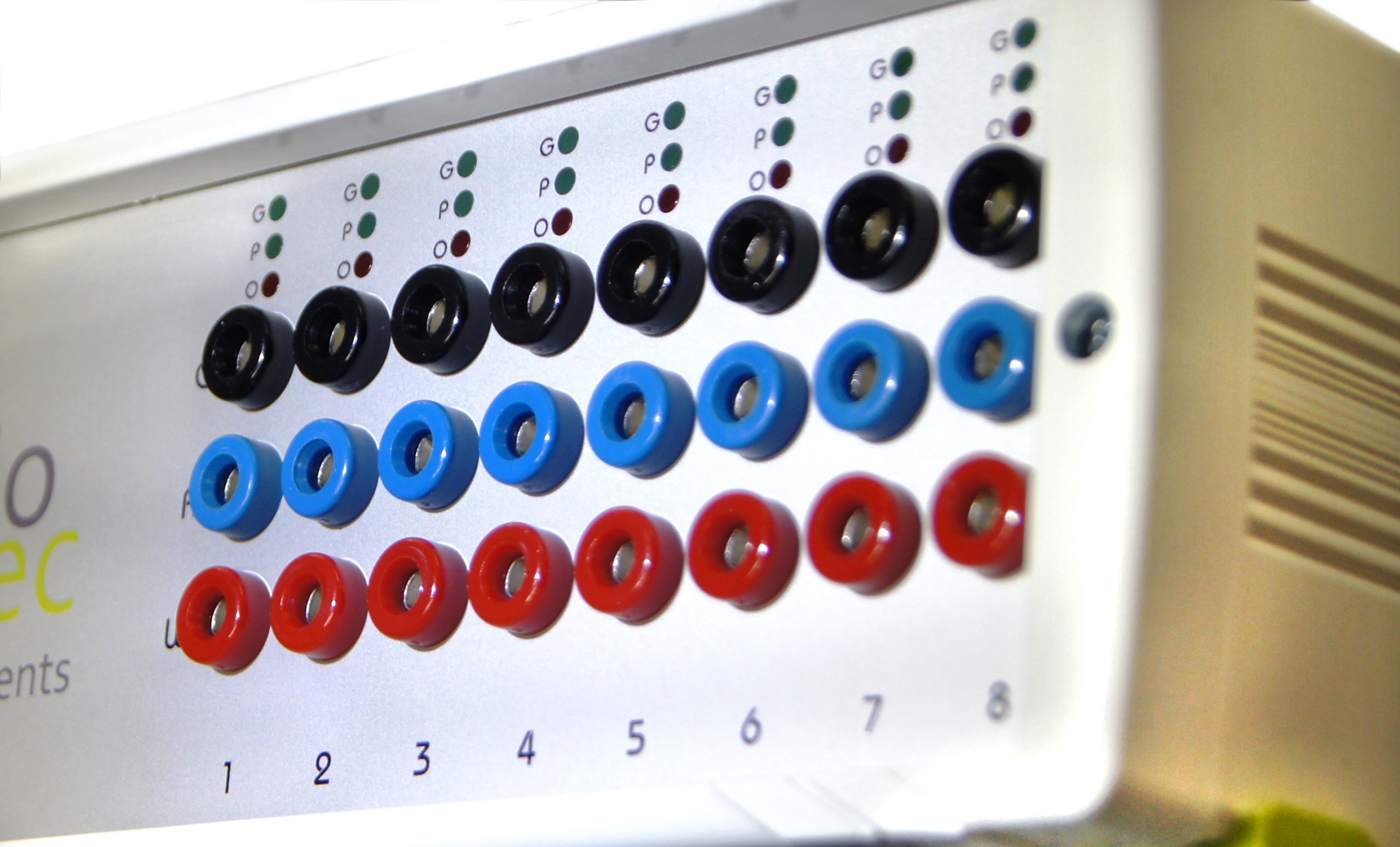

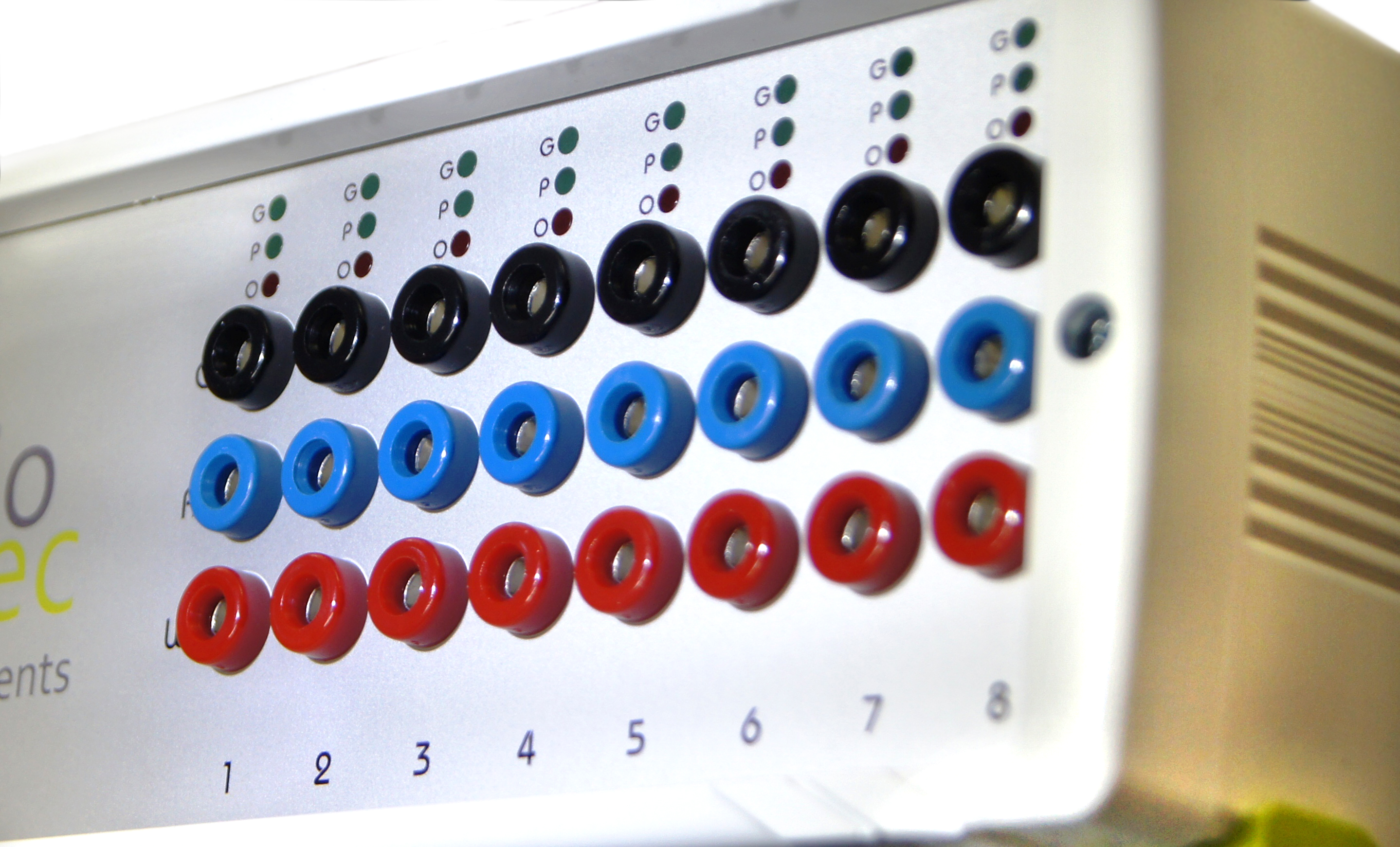

Combinations Multichannel Potentiostat / Galvanostat

All these topologies can be combined to match more complex application requirements. For example each channel of a multi-potentio-/galvanostat can be extended with a multiplexer. Also more sophisticated combinations of multi- and poly-potentiostat-topologies (several poly-potentiostats with several working electrodes each combined in one “multi-polypot”) are feasible.

What we can do for you

Sciospec’s extensive modular platform covers all these topologies and is flexible enough to combine almost any potentio-/galvanostat-requirement with any of them. Apart from our standard solutions the technology platform enables us to create cost effective fully custom solutions. Massive multichannel capabilities and extensive scalability are at the heart of our technology portfolio so whether you need just a few channels in a compact handheld form factor, want to address a newer before seen sensor topology with complex control demands or need to massively scale up a process to several thousand channels – Sciospec is up to the task.

If you have more questions or want to find out how to address your application´s requirements feel free to contact us.